SAFETY AND HEALTH

The Sentinels of Safety award is the oldest established occupational safety award. Herbert Hoover established the award in 1925. The Sentinels of Safety award is co-sponsored by the Mine Safety and Health Administration (MSHA) and the National Mining Association.

Lee Smith Mine being awarded the Sentinels of Safety Award.

Safety and SMD – Our families and clients are counting on us…Our goal is zero harm to our employees.

SMD’s mission statement is to be the leader in safe, productive, and innovative mining solutions. Our core value is to empower, challenge, and reward people to achieve safe, efficient production.

Historically, our safety system was focused on the conditions, training and procedures (the “rules and tools”) to do our work safely. For over ten years our efforts have been focusing on eliminating unsafe behaviors. One of our mining partners, Newmont Mining Corporation, developed a program called the Safety Journey. The Safety Journey describes a path from safety being only awareness to safety being fully integrated into how we do business. We participated in the Safety Journey at Newmont properties we worked in 2011. We liked the program so much, and believed so strongly in the message, that we have adopted this program and are implementing the concepts throughout our organization. We completed our own initial training in 2012 and held company-wide sessions. We updated and held company-wide sessions in 2016, 2022 and 2023. There is real value in getting all employees together and talking about safety.

We continued the Safety Journey in 2013 by incorporating Vital Behaviors. The Vital Behaviors Program is based upon Patterson, Grenny, et al, “Vital Smarts” Six Sources of Influence. Patterson, et al, put forth that we must influence at least four of the six sources of influence to see lasting change in any behavior. We ask our employees to consider their actions in terms of their motivations and abilities and to ensure that these are aligned with safe work practices.

There are 16 common fatality risks identified through studies conducted within the mining industry. SMD has put 10 critical controls in place to prevent or minimize the consequence of the fatality risk. This is done through the daily work process of the operators and maintainers through:

- Line-up meeting reviews,

- In-field Fatal Risk Management System (FRMS) boards, and

- Incorporating critical controls into Field Level Risk Assessments (FLRAs).

Using these tools directly draws on the involvement of the workers performing the task to identify hazards and to properly incorporate controls into our management system. It enables risk-based monitoring through auditing and review of the tasks being performed. It raises awareness and improves the knowledge base among employees who are in the line of fire for a major incident, and it relies on the critical controls to prevent a major incident from occurring. SMD is committed to a safe, productive workplace and works diligently to send all employees home uninjured at the end of their shifts.

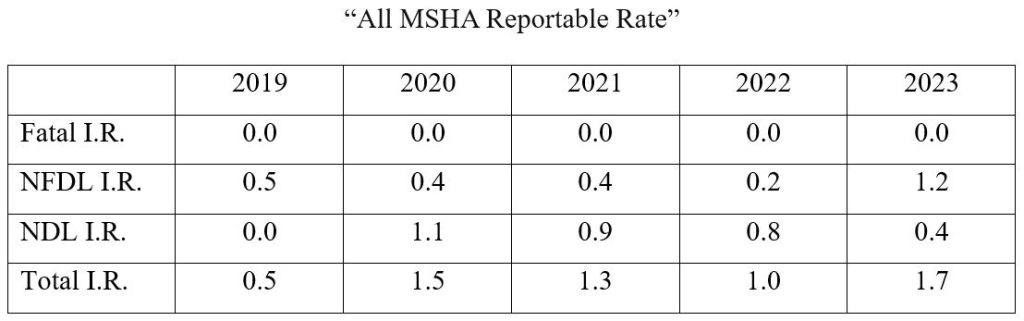

The “All” MSHA Reportable Rate represents the number of MSHA reportable injuries per 200,000 employee-hours worked. The “All” rate, by definition, includes Fatal incidents, Non-Fatal Days Lost, which includes time away from work LTAs, and incidents that result in Restricted Duty, and medical incidents that do not result in restricted duty and the employee is back to work with a full duty release. The definition of an MSHA reportable injury is very well defined and should be relatively standard between companies.

There is always room for improvement and we have remained focused on safety as we continue our Safety Journey.

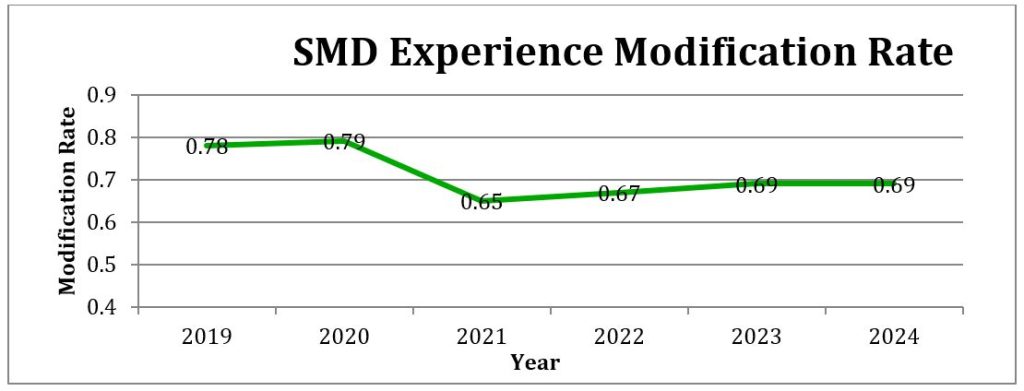

The Experience Modification Rate is utilized by Workman’s Compensation to determine premiums. In theory, a rate of 1.0 would indicate being on par with other underground mining companies. Our Experience Modification Rate has remained below the industry average of 1.0 for over 15 years. We have remained focused on safety, increased our training efforts, and have worked on cultural shifts.

Our safety motto is, “The most important job you have is to go home safe and uninjured at the end of your shift.” This phrase resides on all of our brass boards and serves as a reminder to all personnel that their safety is the most important thing. We provide many tools, both in safety systems and equipment, to help everyone work safely. Our safety system is anchored on the belief that our miners must be able to make decisions and correct situations immediately as their shift progresses. We recognize the importance of, and are committed to maintaining, a constructive and aggressive program to identify and control hazards to life and property.

High-Level Risk Assessments are completed for various tasks we encounter on a daily basis. The Risk Assessment defines the tasks, establishes the risks in a well thought out manner, and then establishes procedures required to perform the task safely. The procedures (SOPs) are documented and reviewed with employees. Task training is also developed based upon results of High-Level Risk Assessment.

Work area inspections are completed utilizing the 5-point safety system. Lead miners or superintendents review everyone’s 5-point cards throughout the workday to ensure employees are working safely. A field level risk assessment is also incorporated into the 5-point safety card to review daily activities as necessary.

We hold daily lineout meetings where immediate concerns are discussed. More in-depth weekly “tool box” meetings are conducted with each and every member of the crew to ensure everyone is working safely. Safety must remain at the forefront of everything we do. If it is not safe, we must make it safe.

We perform task analysis and planned observations as well. We believe that we need to do the job safely and correctly every time. We welcome you to observe us day or night, Monday to Friday, or Saturday and Sunday. We work with the same care and high regard to standards anytime.

We believe safety and efficiency go hand in hand. If you are working safely, it is most likely efficient as well. A select few of our most recent safety accomplishments are listed below.

Sentinels of Safety:

2021 – Sentinels of Safety Award for Large Underground Metal, Lee Smith Mine, 247,400 hours worked safely in 2021.

2014 – Sentinels of Safety Award for Large Underground Metal, MSHA’s Certificate of Achievement in Safety, and Nevada Mining Association’s Underground Operations Small Category (20-99 employees), First Place Winner all at The Lee Smith Mine. Crews here worked 174,710 hours injury free in 2014.

2012 – Sentinels of Safety Winner for the Small Underground Metal Group at the Starvation Canyon project. A total of 90,810 hours were worked without a lost workday injury.

2012 – Sentinels of Safety Winner for the Small Underground Metal Group at the Fire Creek project. A total of 45,715 hours were worked injury free.

2011 – Sentinels of Safety Winner for the Small Underground Metal Group at the Fire Creek project. The portal pad, infrastructure, portal and 2,000 feet of drifting were completed while working 27,250 hours.

2007 – Sentinels of Safety Winner for the Small Underground Metal Group at Cortez Hills. Approximately 9,100 feet of drifting was completed while working 64,860 hours.

In 2016, we received NIOSH’s Mine, Health, and Safety Technology and Innovation Award. Working with J.H. Fletcher, we conceived and constructed a dedicated machine to assist with hanging auxiliary ventilation fans in our operations. The machine removes personnel from working around suspended loads while they hang these fans.

Nevada Mining Association:

Awards received in 2023 for 2022 efforts include:

- Lee Smith Mine, First Place in the Medium size Underground category,

- SSX Mine, Third Place in the Medium size Underground category,

- Leeville Mine – Contractor First Place, 2022

Awards received in 2022 for 2021 efforts include:

- Lee Smith Mine, First Place in the Medium size Underground category,

- SSX Mine, Second Place in the Medium size Underground category,

Awards received in 2021 for 2020 efforts include:

- SSX Mine, Second Place in the Medium size Underground category,

- Lee Smith Mine, First Place in the Small size Underground category,

Awards received in 2020 for 2019 efforts include:

- Marie Sandoval, Safety Manager,

- SSX Mine, First Place in the Medium size Underground category,

- Lee Smith Mine, First Place in the Small size Underground category,

Awards received in 2019 for 2018 efforts include:

- SSX Mine, First Place in the Medium size Underground category,

Contractor Awards,

- Chukar Mine – Contractor First Place,

- Leeville Mine – Contractor First Place,

- Twin Creeks Underground – Contractor First Place.

Awards received in 2018 for 2017 efforts include:

- SSX Mine, Second Place in the Medium size Underground category,

- Smith Mine, First Place in the Small size Underground category, and

- Derek Dawson, Emergency Response and Tom Zitzmann, Safety Champion

Awards received in 2017 for 2016 efforts include:

- Keith Jones, General Manager,

- SSX Mine, Third Place in the Medium size Underground category, and

- Smith Mine, Second Place in the Small size Underground category.

We are also proactive in ensuring the health of our workforce. Our experienced professionals are well versed in ventilation, dust, noise, Diesel Particulate Matter (DPM) and other health issues that directly affect our workforce.

We believe that no job is so important that we cannot take care to perform our work in a safe and healthy manner.

Look to the professionals at SMD for safe, efficient production. We look forward to advancing your project in a safe manner.

And if you want to establish your career with us and are not experienced, we do extensive training for each task we complete. If you have the desire to learn, we will teach you what you need to know to complete the task safely.